METALWORKING CHEMICALS

-

cutting fluid

-

Water-soluble quenching medium

-

Quenching oil

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

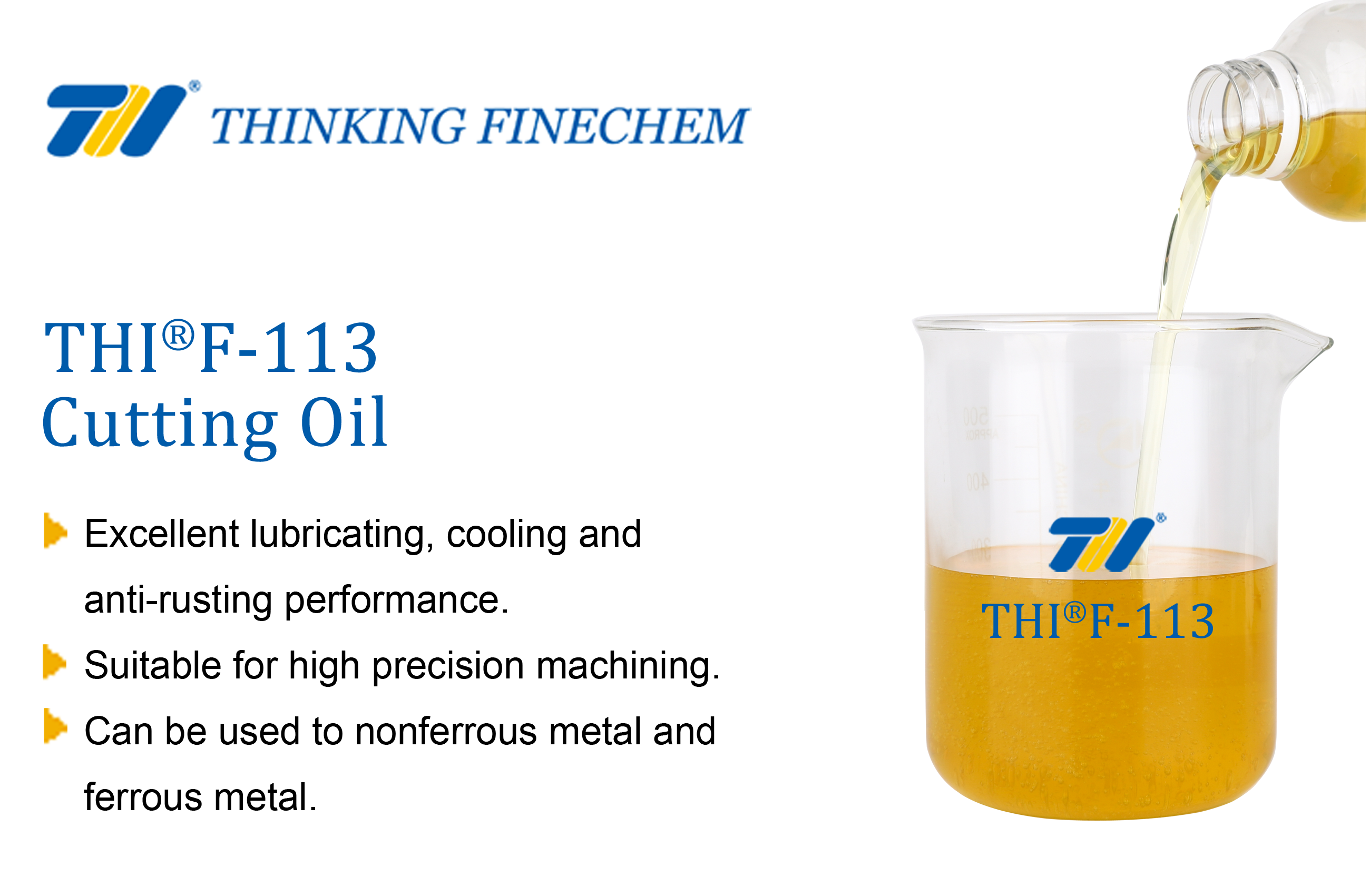

THI®F-113 cutting oil

Brand: Thinking Finechem

Model number:THI®F-113

Appearance: transparent amber-colored liquid

PH:6.5-9.0

package size: 22, 175 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-113

Appearance: transparent amber-colored liquid

PH:6.5-9.0

package size: 22, 175 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is made up of refined mineral oil and a variety of additives including extreme pressure anti-wear agents, rust inhibitors, fungicides, additives, refrigerants, etc. It has good lubricating, cooling, cleaning, and anti-rust performance. It is non-corrosive to the CNC machine tool itself, cutting tools, and workpieces, reducing tool wear and cost. It has a good anti-rust effect on ferrous and non-ferrous metals, and it is non-corrosive to copper, aluminum and other metals. This product can be used directly, or it can be used as an emulsion after mixing with water.

①High pH stability, no smell, long service life of the processing fluid.

②It has excellent lubricity, extreme pressure resistance, cooling and rust resistance. It is specially designed for various extremely difficult cutting processes.

③High lubricity and permeability, which can effectively improve product finish and prolong tool service life.

④It does not contain nitrite, which protects the health of operators.

⑤Non-corrosive to cast iron and non-ferrous metals such as aluminum and copper.

②It has excellent lubricity, extreme pressure resistance, cooling and rust resistance. It is specially designed for various extremely difficult cutting processes.

③High lubricity and permeability, which can effectively improve product finish and prolong tool service life.

④It does not contain nitrite, which protects the health of operators.

⑤Non-corrosive to cast iron and non-ferrous metals such as aluminum and copper.

It can fully meet the technological requirements like high-speed, high-precision, multi-function and high efficiency of modern processing centers and automated production lines.

Processing material: suitable for general non-ferrous metals (aluminum, copper, etc.) and ferrous metals.

Processing method: suitable for turning, grinding, milling, drilling, boring, reaming, tapping, etc.

Processing material: suitable for general non-ferrous metals (aluminum, copper, etc.) and ferrous metals.

Processing method: suitable for turning, grinding, milling, drilling, boring, reaming, tapping, etc.

①dilute with water: Prepare the cutting fluid with a concentration of 5%-10%. Used Purified water if possible. It is not necessary to replace all of the cutting fluid during use, just replenish the new fluid regularly according to the use concentration.

②Direct use: Clean up the waste oil in the cutting oil tank, and then add this product to the oil storage tank of the equipment. Do not overfill the tank to avoid waste. When replenishing the oil, just add it directly.

②Direct use: Clean up the waste oil in the cutting oil tank, and then add this product to the oil storage tank of the equipment. Do not overfill the tank to avoid waste. When replenishing the oil, just add it directly.

① Avoid mixing with other cutting oils that are not from our company to prevent adverse reactions.

②Replenishment and maintenance of the solution in tank: When the tank solution needs to be replenished, add a corresponding proportion of the original cutting oil while adding water to maintain the necessary concentration. Never add water only without cutting oil.

②Replenishment and maintenance of the solution in tank: When the tank solution needs to be replenished, add a corresponding proportion of the original cutting oil while adding water to maintain the necessary concentration. Never add water only without cutting oil.

22, 175 KG / barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.