METALWORKING CHEMICALS

- Corrosion inhibitor /fogging inhibitor

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

-

Special lubricants

-

Water treatment agents

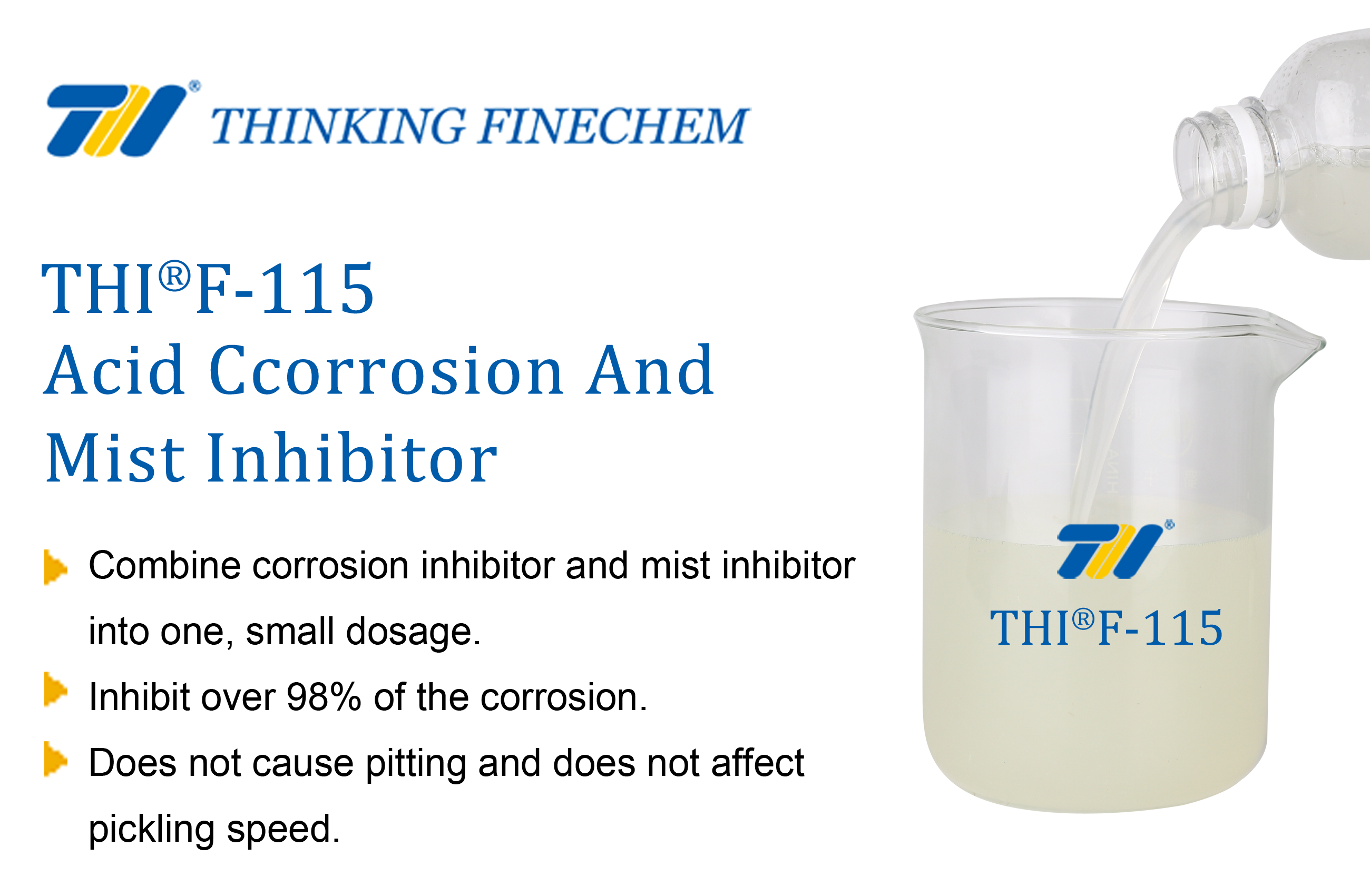

THI®115 acid corrosion and mist inhibitor

Brand: Thinking Finechem

Model number:THI®F-115

Appearance: yellowish liquid

PH:6.0-8.0

package size: 25, 200 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-115

Appearance: yellowish liquid

PH:6.0-8.0

package size: 25, 200 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product can effectively inhibit corrosion caused by various chemical cleaning acids, prevents pitting caused by over-corrosion, reduce acid usage, and inhibit the volatilization of acid mist.

① It has a good corrosion inhibition effect without affecting the acid cleaning (pickling) speed. It has a corrosion inhibition rate of over 98%.

②Protect the workpiece from acid corrosion, prevent excessive acid cleaning, and save 15-20% of the pickling agent usage, which is cost-efficient.

③It has excellent resistance to hydrogen permeation during pickling and can inhibit Fe3+ corrosion, no pitting corrosion occurs during acid cleaning, and it improves the surface finish of the workpiece after acid cleaning.

④ No adverse effects on the subsequent processes after acid cleaning. No adverse effects on acid recycling and regeneration.

⑤ Stable performance, small dosage, high efficiency and wide range of application.

⑥ It also has a certain mist suppression effect, which can effectively control the acid mist brought out by hydrogen emission, improve the working environment, and reduce the corrosion of workshop equipment.

②Protect the workpiece from acid corrosion, prevent excessive acid cleaning, and save 15-20% of the pickling agent usage, which is cost-efficient.

③It has excellent resistance to hydrogen permeation during pickling and can inhibit Fe3+ corrosion, no pitting corrosion occurs during acid cleaning, and it improves the surface finish of the workpiece after acid cleaning.

④ No adverse effects on the subsequent processes after acid cleaning. No adverse effects on acid recycling and regeneration.

⑤ Stable performance, small dosage, high efficiency and wide range of application.

⑥ It also has a certain mist suppression effect, which can effectively control the acid mist brought out by hydrogen emission, improve the working environment, and reduce the corrosion of workshop equipment.

①Suitable for acid washing of carbon steel, low alloy steel, stainless steel, copper, aluminum and other metals and different materials.

②Suitable for various boilers, coolers, heaters, reactors, internal combustion engine cooling systems, receptacles, water and sewage systems, air conditioning systems and other equipment.

③Suitable for acid washing with various inorganic acids, organic acids and mixed acids such as hydrochloric acid, nitric acid, sulfuric acid, hydrofluoric acid, citric acid, sulfamic acid, oxalic acid, phosphoric acid, acetic acid, etc.

②Suitable for various boilers, coolers, heaters, reactors, internal combustion engine cooling systems, receptacles, water and sewage systems, air conditioning systems and other equipment.

③Suitable for acid washing with various inorganic acids, organic acids and mixed acids such as hydrochloric acid, nitric acid, sulfuric acid, hydrofluoric acid, citric acid, sulfamic acid, oxalic acid, phosphoric acid, acetic acid, etc.

① Directly add the acid corrosion and mist inhibitor to the newly prepared pickling solution, and the amount of addition is 0.1%-0.15% of the total amount of pickling solution.

②if additional pickling agent is replenished during pickling, replenish the acid corrosion and mist inhibitor in the above proportion accordingly.

③The temperature and time of the pickling process stays the same as the original requirements of the production process.

②if additional pickling agent is replenished during pickling, replenish the acid corrosion and mist inhibitor in the above proportion accordingly.

③The temperature and time of the pickling process stays the same as the original requirements of the production process.

Wear safety protection equipment when using. Be careful to not splash the liquid on the body. If the liquid is splashed on the body accidentally, wash with plenty of water immediately.

25KG, 200KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.