METALWORKING CHEMICALS

-

Pickling and passivation paste for stainless steel

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

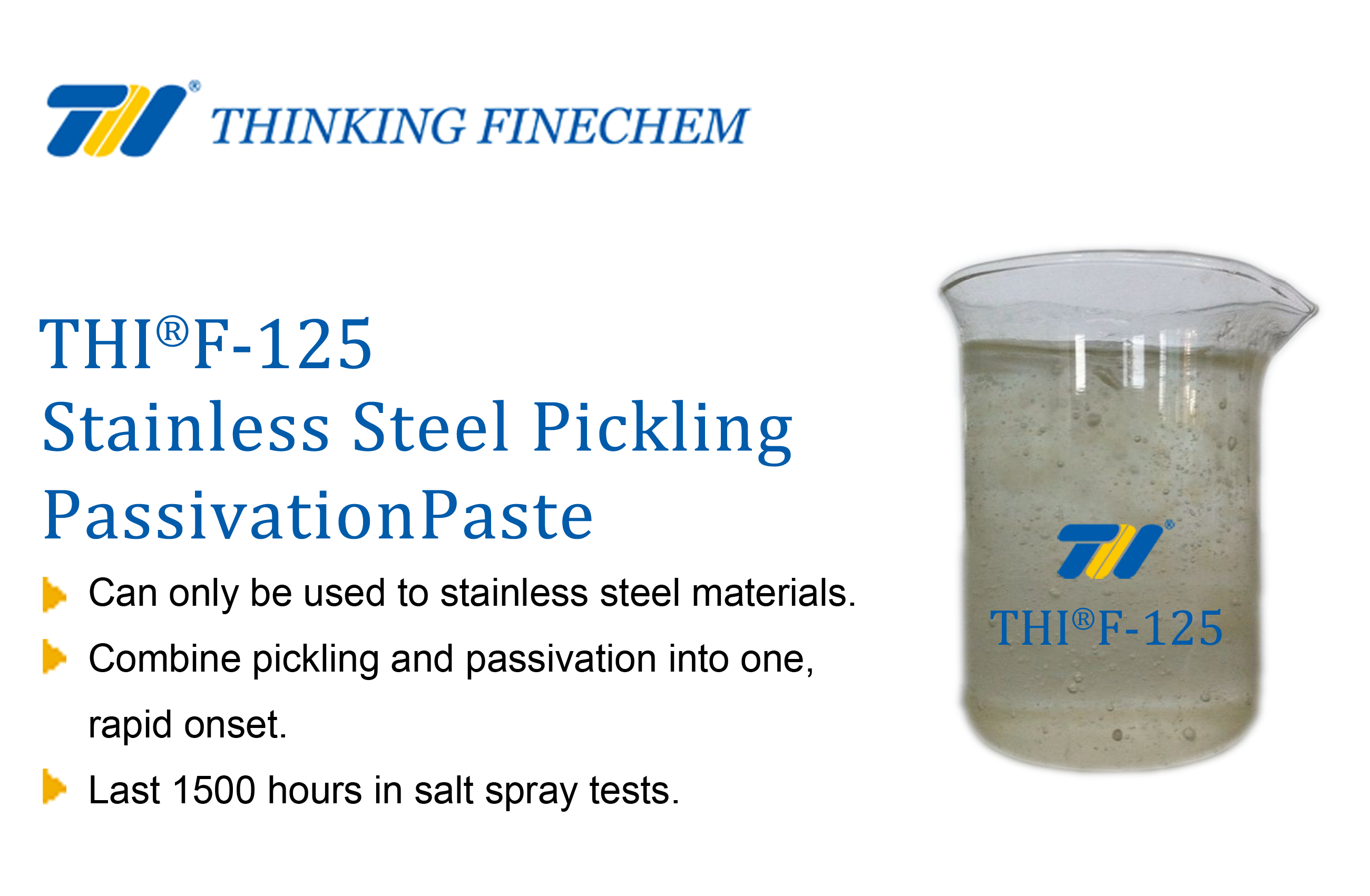

THI®F-125 stainless steel pickling and passivation paste

Brand: Thinking Finechem

Model number:THI®F-125

Appearance: transparent paste

Suitable for: stainless steel

package size: 24 bottles/box or 25 KG/bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-125

Appearance: transparent paste

Suitable for: stainless steel

package size: 24 bottles/box or 25 KG/bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is used for pickling and passivation of welding joints and surfaces of large stainless steel workpieces to remove the oxide scale produced after welding and high temperature processing. After treatment, the surface of stainless steel becomes silvery white and forms a passivation film, which can improve the surface anti-corrosion ability of stainless steel and extends the service life of the equipment.

①Pickling and passivation processes are completed together. Fast reaction, thorough cleaning, no mottling, and non-corrosive to the metal surface.

②Simple operation process, strong adhesion, easy to observe the effect.

③The treated stainless steel surface has fine luster and uniform surface color, forming a silver-white matte passivation film, which can pass the blue dot test.

④The corrosion resistance of stainless steel is significantly improved. It can reach 1500 hours in the salt spray test. This pickling and passivation paste can prolong the service life of the product and increase the added value of the product.

②Simple operation process, strong adhesion, easy to observe the effect.

③The treated stainless steel surface has fine luster and uniform surface color, forming a silver-white matte passivation film, which can pass the blue dot test.

④The corrosion resistance of stainless steel is significantly improved. It can reach 1500 hours in the salt spray test. This pickling and passivation paste can prolong the service life of the product and increase the added value of the product.

Suitable for pickling and passivation of stainless steel materials, 300 series austenitic stainless steel parts, plates and equipment. It is widely used in the surface treatment of stainless steel machinery, pressure vessels, engineering components in the chemical, food, printing and dyeing, aviation and other industries.

First clean up the welding slag and oil stains on the surface, apply an appropriate amount of stainless steel pickling and passivation paste to the surface of the stainless steel with a thickness of 1-2 mm, and leave it for 5-30 minutes or longer (depending on the dirt, plate material and processing requirements). Then wipe off the residue on the cleaned surface with a rag and rinse with clean water.

①It must be operated outdoors or indoors with good ventilation.

②Operators should wear protective equipment such as rubber gloves and masks. When operating in a closed environment, ventilation equipment must be used. The operator’s skin should not come into contact with this product. If the product touches the skin accidentally, rinsed immediately with water (or with 5% sodium bicarbonate solution).

③The container of stainless steel pickling and passivation paste should be corrosion resistant stainless steel or plastic products, and it cannot be in contact with welded steel.

④Do not operate under the sun to prevent the stainless steel pickling and passivation paste from drying and affect the passivation effect.

②Operators should wear protective equipment such as rubber gloves and masks. When operating in a closed environment, ventilation equipment must be used. The operator’s skin should not come into contact with this product. If the product touches the skin accidentally, rinsed immediately with water (or with 5% sodium bicarbonate solution).

③The container of stainless steel pickling and passivation paste should be corrosion resistant stainless steel or plastic products, and it cannot be in contact with welded steel.

④Do not operate under the sun to prevent the stainless steel pickling and passivation paste from drying and affect the passivation effect.

24 bottles/box or 25 KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.