METALWORKING CHEMICALS

-

Pickling and passivation paste for stainless steel

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

THI®F-126 stainless steel pickling and passivation agent

Brand: Thinking Finechem

Model number:THI®F-126

Appearance: transparent colorless liquid

Suitable for: stainless steel

package size: 25, 200 / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-126

Appearance: transparent colorless liquid

Suitable for: stainless steel

package size: 25, 200 / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product completely cleans and passivates stainless steel. It removes all kinds of scales, fingerprints, floating rust and dirt. After the treatment, the surface of the stainless steel becomes silvery white, and a passivation film is formed. This product can both clean and passivate the stainless steel and also improve the corrosion resistance of stainless steel.

①Stainless steel pickling and passivation processes are completed together. This product completely cleans and passivates stainless steel. After treatment, the surface forms uniform silver-white film and can pass the blue dot test.

②high-efficiency corrosion inhibitors and fog inhibitors are added to this agent to prevent excessive corrosion and hydrogen embrittlement of metals and inhibit the generation of acid fog.

③Simple operation, convenient to use, time-saving.

④The corrosion resistance can be increased by 5-20 times. This agent can last 1500 hours in the neutral salt spray test.

②high-efficiency corrosion inhibitors and fog inhibitors are added to this agent to prevent excessive corrosion and hydrogen embrittlement of metals and inhibit the generation of acid fog.

③Simple operation, convenient to use, time-saving.

④The corrosion resistance can be increased by 5-20 times. This agent can last 1500 hours in the neutral salt spray test.

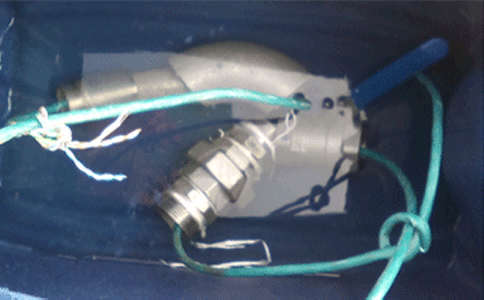

It is suitable for the surface treatment of 300 series austenitic stainless steel (303, 304, 316, 316L, etc.), especially for small and complex stainless steel workpieces. It is suitable for chemical machinery, petrochemical equipment, stainless steel production, mechanical processing, stainless steel processing, head plate and hardware production industries.

①Small stainless steel parts can be soaked in a container, and the original solution can be directly used. The recommended soaking time is 5-15 minutes in summer and 20-30 minutes in winter (if the oxide layer is thick and there is much dirt, the soaking time can be extended appropriately). Each kilogram of passivation liquid can treat a stainless steel surface area of 60-70 square meters.

②Rinse with clean water after cleaning.

③For larger equipment or pipelines, use pumps for circulating spraying to treat the workpiece. Then rinse with clean water to ensure that there is no residue.

②Rinse with clean water after cleaning.

③For larger equipment or pipelines, use pumps for circulating spraying to treat the workpiece. Then rinse with clean water to ensure that there is no residue.

①washing tank: The tank for pickling and passivation should be acid-resistant plastic tank or FRP tank.

②Addition and maintenance of tank liquid: regularly clean up the impurities and residues in the tank. When the performance of the fluid drops, replenish the pickling and passivation agent in the tank

③Be equipped with protective equipment such as rubber gloves and goggles during operation. The skin should not be in contact with this product. Wash with plenty of water if touched accidentally.

②Addition and maintenance of tank liquid: regularly clean up the impurities and residues in the tank. When the performance of the fluid drops, replenish the pickling and passivation agent in the tank

③Be equipped with protective equipment such as rubber gloves and goggles during operation. The skin should not be in contact with this product. Wash with plenty of water if touched accidentally.

225KG, 200KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.