METALWORKING CHEMICALS

-

Special lubricants

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Water treatment agents

THI®F-3611 cleaning agent for heat conduction oil

Brand: Thinking Finechem

Model number:THI®F-3611

Appearance: yellowish liquid

pH: neutral

package size: 170 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-3611

Appearance: yellowish liquid

pH: neutral

package size: 170 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is specially used to clean the heavy grease, oil coke, oil sludge in the heat conduction equipment and the oxidized grease and carbon deposits formed in various heat conduction oil furnaces. The product can be used directly. It cannot be mixed with water or heated. It can quickly and safely dissolve all kinds of oil, grease and coke. This product has excellent permeability and can easily remove oil coke. The cleaning efficiency is about 6 times that of kerosene. It is simple and convenient to use. It is eco-friendly and can be recycled and reused.

①Quickly remove grease and carbon deposits on the internal pipes and heat exchangers of the heat-conducting oil furnace, leaving no residue.

②Neutral and non-corrosive, completely harmless to the internal pipes of the heat-conducting oil furnace and the heat conducting surface of the heat exchanger metal (iron, copper, aluminum, stainless steel, etc.).

③It is safe to use, this product does not corrode the cleaned objects, has little irritation, and does not cause damage to the skin.

④Reusable, low cleaning cost.

②Neutral and non-corrosive, completely harmless to the internal pipes of the heat-conducting oil furnace and the heat conducting surface of the heat exchanger metal (iron, copper, aluminum, stainless steel, etc.).

③It is safe to use, this product does not corrode the cleaned objects, has little irritation, and does not cause damage to the skin.

④Reusable, low cleaning cost.

It is suitable for cleaning heavy grease, oil tar and oil sludge in the heat conduction oil system.

1、Cleaning of heat conduction oil furnace system

①Drain the used oil: Use the heating system to heat the heat conduction oil to 70-80℃, and discharge all the heat conduction oil in the system while it is hot. The residual oil in the system can be released as much as possible according to the system conditions, and cleaning agent can be added to release the remaining oil by penetrating, peeling and dissolving to dilute the oil and discharge it out of the system.

②After draining the oil, check the temperature of the furnace and the pipeline. Add the cleaning agent when the temperature drops to room temperature.

③Add cleaning agent: add it from the high tank or any part of the heating system, turn on the circulating pump for circulate cleaning at room temperature. Switch the system valve so that all parts in the system can be cleaned. The valve switching should be done every hour. The entire cleaning time should be no less than 12 hours. After cleaning, recycle the cleaning fluid and save it for next time to use.

④After the discharge is completed, if the system conditions permit, compressed air can be used to purge the remaining cleaning agent in the system until it is drained.

⑤Add new oil: add new heat conduction oil into the system.

2、Cleaning of the thermal oil heating reactor

(1)Determine the amount of cleaning agent

The amount of cleaning agent is the minimum circulation amount of the system volume. This amount can ensure that the circulation system is normally immersed and can completely cover the oil cock and grease in the equipment.

(2) Determine the cleaning time

The cleaning time is 12 hours to 24 hours.

(3) Connect the cleaning pipeline

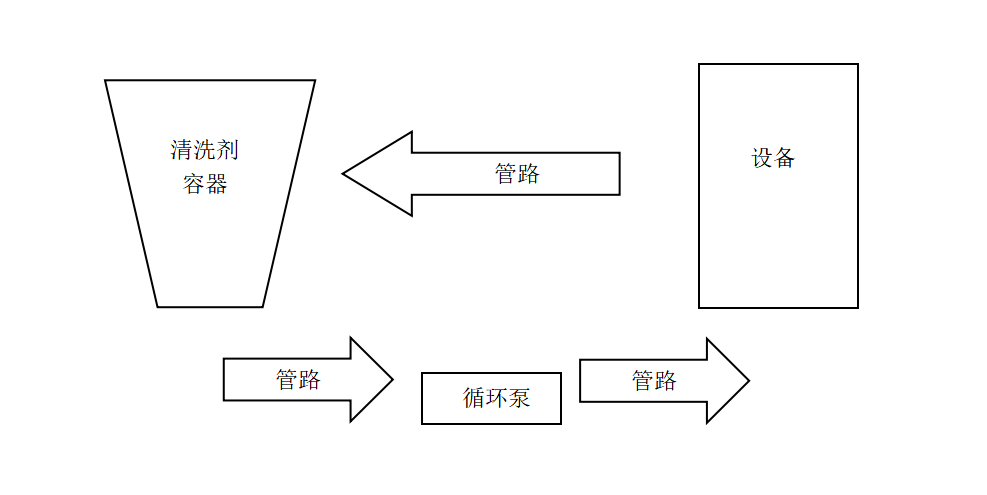

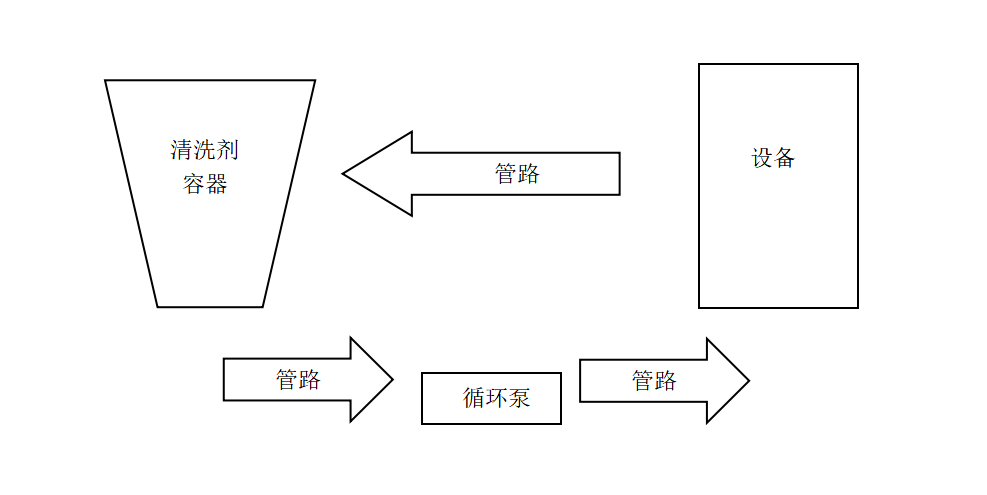

As shown below:

(4) Cleaning

(4) Cleaning

Check the circulation pipeline and keep the system unblocked.

Cleaning: add the cleaning agent into the container, turn on the circulating pump to inject the cleaning agent into the equipment without heating, and use it at room temperature. Switch the system valve so that all parts in the system can be cleaned. The valve switching should be done every hour. The entire cleaning time is 12-24 hours (if the oil layer in the system is thick, additional cleaning time is needed). Open any part of the circulation pipeline to check the cleaning situation. If there is still grease, extend the cleaning time until all the grease is peeled off and then enter the next step.

Emptying: discharge all the cleaning agent and grease in the equipment into the cleaning agent container, use an air compressor to purge the residual liquid in the equipment.

Recycle of cleaning agent: After cleaning, the cleaning solution can be recycled and is ready for next use.

①Drain the used oil: Use the heating system to heat the heat conduction oil to 70-80℃, and discharge all the heat conduction oil in the system while it is hot. The residual oil in the system can be released as much as possible according to the system conditions, and cleaning agent can be added to release the remaining oil by penetrating, peeling and dissolving to dilute the oil and discharge it out of the system.

②After draining the oil, check the temperature of the furnace and the pipeline. Add the cleaning agent when the temperature drops to room temperature.

③Add cleaning agent: add it from the high tank or any part of the heating system, turn on the circulating pump for circulate cleaning at room temperature. Switch the system valve so that all parts in the system can be cleaned. The valve switching should be done every hour. The entire cleaning time should be no less than 12 hours. After cleaning, recycle the cleaning fluid and save it for next time to use.

④After the discharge is completed, if the system conditions permit, compressed air can be used to purge the remaining cleaning agent in the system until it is drained.

⑤Add new oil: add new heat conduction oil into the system.

2、Cleaning of the thermal oil heating reactor

(1)Determine the amount of cleaning agent

The amount of cleaning agent is the minimum circulation amount of the system volume. This amount can ensure that the circulation system is normally immersed and can completely cover the oil cock and grease in the equipment.

(2) Determine the cleaning time

The cleaning time is 12 hours to 24 hours.

(3) Connect the cleaning pipeline

As shown below:

(4) Cleaning

(4) CleaningCheck the circulation pipeline and keep the system unblocked.

Cleaning: add the cleaning agent into the container, turn on the circulating pump to inject the cleaning agent into the equipment without heating, and use it at room temperature. Switch the system valve so that all parts in the system can be cleaned. The valve switching should be done every hour. The entire cleaning time is 12-24 hours (if the oil layer in the system is thick, additional cleaning time is needed). Open any part of the circulation pipeline to check the cleaning situation. If there is still grease, extend the cleaning time until all the grease is peeled off and then enter the next step.

Emptying: discharge all the cleaning agent and grease in the equipment into the cleaning agent container, use an air compressor to purge the residual liquid in the equipment.

Recycle of cleaning agent: After cleaning, the cleaning solution can be recycled and is ready for next use.

170KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.