METALWORKING CHEMICALS

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

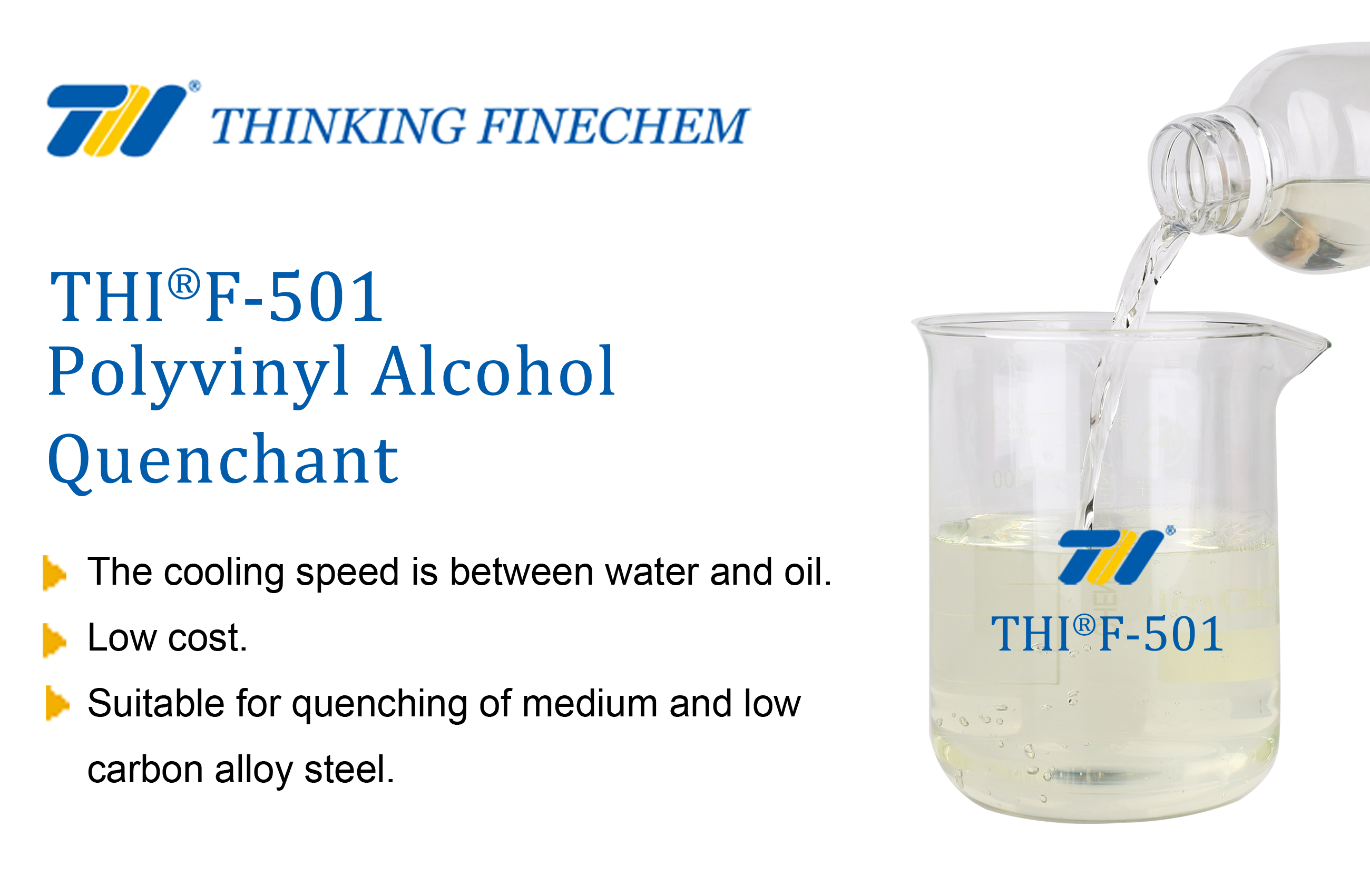

THI®F-501 Polyvinyl alcohol (PVA) quenchant

Brand: Thinking Finechem

Model number:THI®F-501

Appearance: colorless or yellowish, uniformly dissolved liquid

PH:6.0-8.0

package size: 200KG/ barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-501

Appearance: colorless or yellowish, uniformly dissolved liquid

PH:6.0-8.0

package size: 200KG/ barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is a light yellowish translucent concentrate. It solves the problems of fast water cooling, cracking of the workpiece, slow oil cooling, poor quenching effect and flammability. Dilute the quenchant with a certain proportion of water according to the quenching process requirements of the workpiece before use, so that the quenching performance can be adjusted freely between water and oil. This product has low price and has a wide range of application.

①By adjusting the concentration of the aqueous solution, the cooling capacity can be adjusted in a wide range. The cooling rate can be adjusted to close to water, between water and oil, close to oil or even slower than oil to meet the quenching requirements of different materials and workpieces.

②This product is smokeless, non-corrosive, non-flammable, safe to use, and free of environmental pollution.

③This product can be used to replace oil quenching and can reduce the process cost by about 80%. The workpiece obtained after quenching is clean and has a certain anti-rust ability.

④When quenching with this product, the cooling rate is faster at the beginning of quenching, and the cooling rate is slower in the boiling stage. This helps to obtain martensite. When entering the convection stage, its cooling capacity is much slower than water, which can reduce the tendency of distortion and cracking of workpiece.

②This product is smokeless, non-corrosive, non-flammable, safe to use, and free of environmental pollution.

③This product can be used to replace oil quenching and can reduce the process cost by about 80%. The workpiece obtained after quenching is clean and has a certain anti-rust ability.

④When quenching with this product, the cooling rate is faster at the beginning of quenching, and the cooling rate is slower in the boiling stage. This helps to obtain martensite. When entering the convection stage, its cooling capacity is much slower than water, which can reduce the tendency of distortion and cracking of workpiece.

| Subject | Indicator |

|---|---|

| Appearance | colorless or yellowish, uniformly dissolved liquid (translucent) |

| Solid content | 10-12% |

| PH | 6.0-8.0 |

| Viscosity (based on QND-1 viscometer) | 20-50s |

| Conductivity | 0.2-0.3s/m |

This product has been widely used in induction heating quenching and is mostly used for high-frequency and medium-frequency quenching of carbon steel and alloy steel. In addition, this product can also be used for quenching of integrally heated workpieces. For example: 40Cr, 40CrMo, 40Mn2, 45Mn2, 30CrMnSi steel, GCr15, 9CrSi steel and other rolls quenching; 42CrMo, Cr12, Cr12Mo and other mold quenching. It is also suitable for quenching of steel parts such as 45Cr, 20CrMo, 35CrMo, 40CrMnMo, 45CMnB, 45CMnB, 40Mn3, 45Mn3, 42CrNi, 9Cr3, 3Cr2W8, 50Mo, etc. The concentration is usually 3-5%.

①Concentration control: In the quenching medium, as the concentration of this product increases, the cooling capacity of the medium decreases significantly. In order to ensure that the workpiece reaches the required hardness without causing quenching cracks, the concentration of the quenching medium must be stabilized within a certain range. During work, the concentration of the quenching medium will gradually decrease due to the quenching medium is constantly taken away by the quenched workpiece. In order to stabilize the concentration of the quenching medium within the required range, the concentration of the medium is generally controlled by replenishing the stock solution of quenchant regularly (weekly or every ten days). The specific time depends on the frequency of use and production experience.

②Temperature control: The temperature of the quenching medium has a certain relationship with the cooling performance. As the temperature rises, the cooling rate becomes slower. When the liquid temperature exceeds 50°C, the cooling rate changes greatly. Therefore, generally the liquid temperature should be controlled at 20-45°C.

③This product is not suitable for the quenching of parts heated by the salt furnace, because the inorganic salt brought in during operation will cause decomposition of the water-based quenchant, resulting in changes in cooling performance.

②Temperature control: The temperature of the quenching medium has a certain relationship with the cooling performance. As the temperature rises, the cooling rate becomes slower. When the liquid temperature exceeds 50°C, the cooling rate changes greatly. Therefore, generally the liquid temperature should be controlled at 20-45°C.

③This product is not suitable for the quenching of parts heated by the salt furnace, because the inorganic salt brought in during operation will cause decomposition of the water-based quenchant, resulting in changes in cooling performance.

①In order to extend the service life of the quenching medium, pay attention to proper stirring during use. proper stirring can ensure the unify performance of the quenching medium. Usually use a pump or a propeller to stir. When stirring with a pump, the flow rate of the quenching medium should be less than one meter per second to avoid air being drawn into the liquid; when stirring with a propeller, the speed should be 100-450 revolutions per minute. Frequent stirring can prevent the formation of mold and can cause the small amount of existing mold to die after being exposed to light. Another way to prevent mildew of the medium is to add an appropriate amount of preservative (such as sodium benzoate) to the medium.

②The operating life of quenching medium is mainly determined by the production situation and the cleanliness of maintenance. Experiments shows that the usage period ranges from 6 months to three years.

③This product is not cold-resistant, so it should be stored and transported at a temperature above 5℃. If it is frozen and crystallized, it will lose efficacy. Because it cannot be transported in winter, users should stock the winter dosage before winter. the product should be stored in a cool place.

②The operating life of quenching medium is mainly determined by the production situation and the cleanliness of maintenance. Experiments shows that the usage period ranges from 6 months to three years.

③This product is not cold-resistant, so it should be stored and transported at a temperature above 5℃. If it is frozen and crystallized, it will lose efficacy. Because it cannot be transported in winter, users should stock the winter dosage before winter. the product should be stored in a cool place.

The national sewage discharge standard is 100mg/L. The biological oxygen consumption of HXZ-Ⅱ water-soluble synthetic quenchant is 68.4mg/L, which is lower than the national pollution discharge standard, so it can be discharged freely. If the concentration of the medium is high for some reason, it can be diluted with clean water to make its biological oxygen consumption lower than the national pollution discharge standard.

200KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.