METALWORKING CHEMICALS

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

THI®F-505 Inorganic polymer quenchant

Brand: Thinking Finechem

Model number:THI®F-505

Appearance: colorless or yellowish liquid

PH:5.0-8.0

package size: 25, 200KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-505

Appearance: colorless or yellowish liquid

PH:5.0-8.0

package size: 25, 200KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is a saturated solution of macromolecular inorganic polymer. The inorganic quenchant is prepared in proportion with water. It has a cooling rate greater than water at high temperature, and much lower cooling rate than water at low temperature, especially at 300°C, the cooling rate is close to oil.

①No oil fume, no fire hazard, and clean production environment.

②High cooling rate in high temperature zone, strong hardenability, high and uniform workpiece hardness, deep hardened layer.

③The low temperature cooling rate is obviously low, which can reduce the distortion, warpage and cracking of the workpiece.

④Wide range of application temperature, usually in the range of 30℃-60℃.

⑤Good manufacturability. As the hardenability is improved and the quenching time is reduced by our quenchant, the production efficiency can be increased by 20%-30% and the energy can be saved by 10%.

⑥ Good thermal stability, no aging, anti-pollution, no decomposition at high temperature, no deterioration, and can be used for a long time.

②High cooling rate in high temperature zone, strong hardenability, high and uniform workpiece hardness, deep hardened layer.

③The low temperature cooling rate is obviously low, which can reduce the distortion, warpage and cracking of the workpiece.

④Wide range of application temperature, usually in the range of 30℃-60℃.

⑤Good manufacturability. As the hardenability is improved and the quenching time is reduced by our quenchant, the production efficiency can be increased by 20%-30% and the energy can be saved by 10%.

⑥ Good thermal stability, no aging, anti-pollution, no decomposition at high temperature, no deterioration, and can be used for a long time.

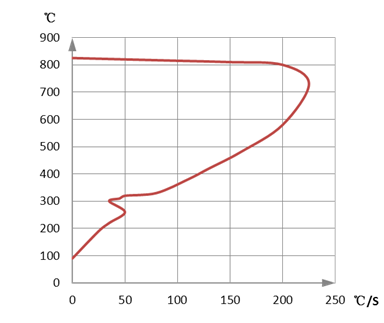

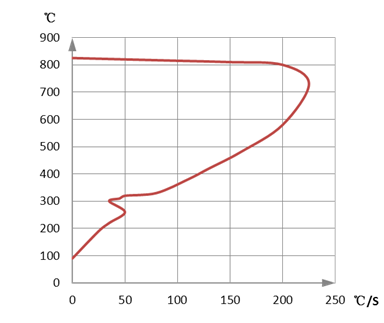

The 30℃ cooling characteristic curve after the quenchant being diluted in a ratio of 3:7.

Suitable for the quenching of steel parts such as carburizing steel, carbonitriding steel, carbon steel, medium and low alloy steel, medium and low hardenability structural steel. It can be used for the integral immersion quenching and spray quenching of various furnace heating steel parts and induction heating workpieces.

Dilute with water in a ratio of 3:7 and stir until the solution is well mixed.

25KG, 200KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.