METALWORKING CHEMICALS

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

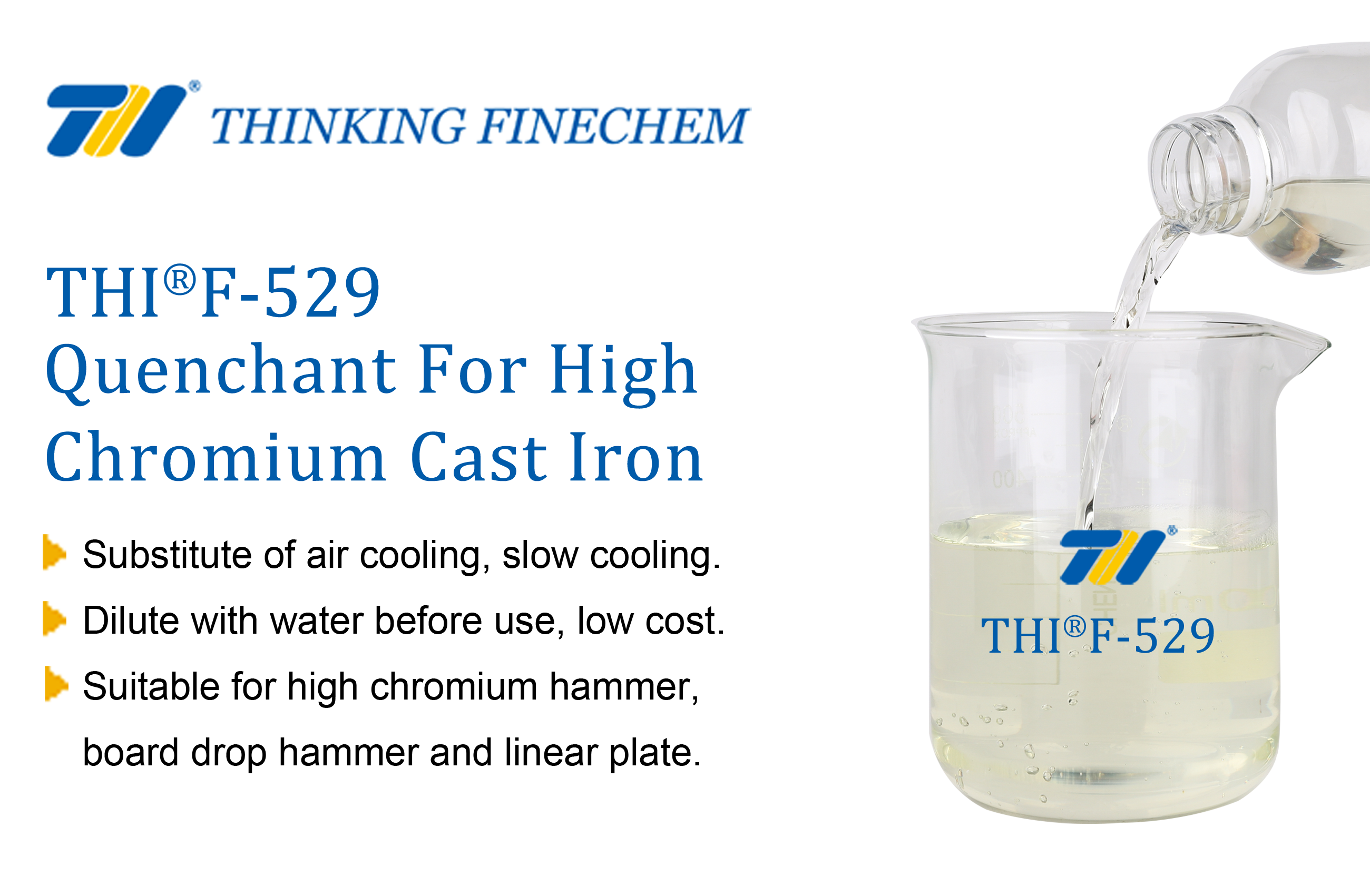

THI®F-529 quenchant for high chromium cast iron

Brand: Thinking Finechem

Model number:THI®F-529

Appearance: colorless to yellowish liquid

PH:9.0-11.0

package size: 25, 200KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-529

Appearance: colorless to yellowish liquid

PH:9.0-11.0

package size: 25, 200KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is an aqueous solution which can be diluted with different amount of water. It has the functions of rust prevention, sterilization and corrosion protection. It is non-flammable, no fire hazard, harmless to operators and the environment, less likely to age, and has a long service life.

①Adjusting the concentration of the aqueous solution to meet the quenching requirements of different materials and different sizes of workpieces. The cooling rate is slightly faster than oil and much slower than water.

②This product has high viscosity. It can form hard film which is not easy to break. Therefore, sometimes a layer of foam will form in the quenching bath, and a hard skin will form on the surface if it is not used for a period of time. This is a normal phenomenon and does not affect the quenching effect. The hard surface skin will disappear after the temperature of quenching liquid rises.

②This product has high viscosity. It can form hard film which is not easy to break. Therefore, sometimes a layer of foam will form in the quenching bath, and a hard skin will form on the surface if it is not used for a period of time. This is a normal phenomenon and does not affect the quenching effect. The hard surface skin will disappear after the temperature of quenching liquid rises.

It is suitable for high-chromium alloy materials such as small and medium-sized board hammers, hammerheads, liners, various types of high-chromium grinding balls and other products, as well as high, medium and low-chromium alloy steels, alloy tool steels and high-speed steel products.

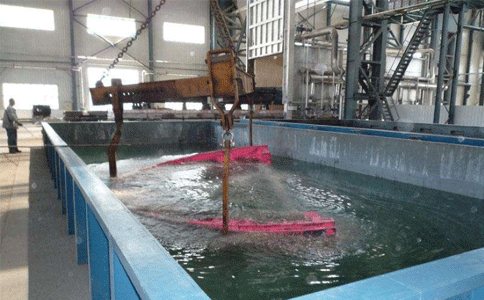

The dilution ratio of quenchant to water is 1:6, and the ratio of diluted quenching liquid to the weight of the high chromium workpiece is 1:3. The specific usage ratio is determined according to the environmental temperature and production conditions. Lower ratio is used in winter.

25KG, 200KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.