METALWORKING CHEMICALS

-

Special lubricants

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

-

Forging releasing agent

- Corrosion inhibitor /fogging inhibitor

-

Water treatment agents

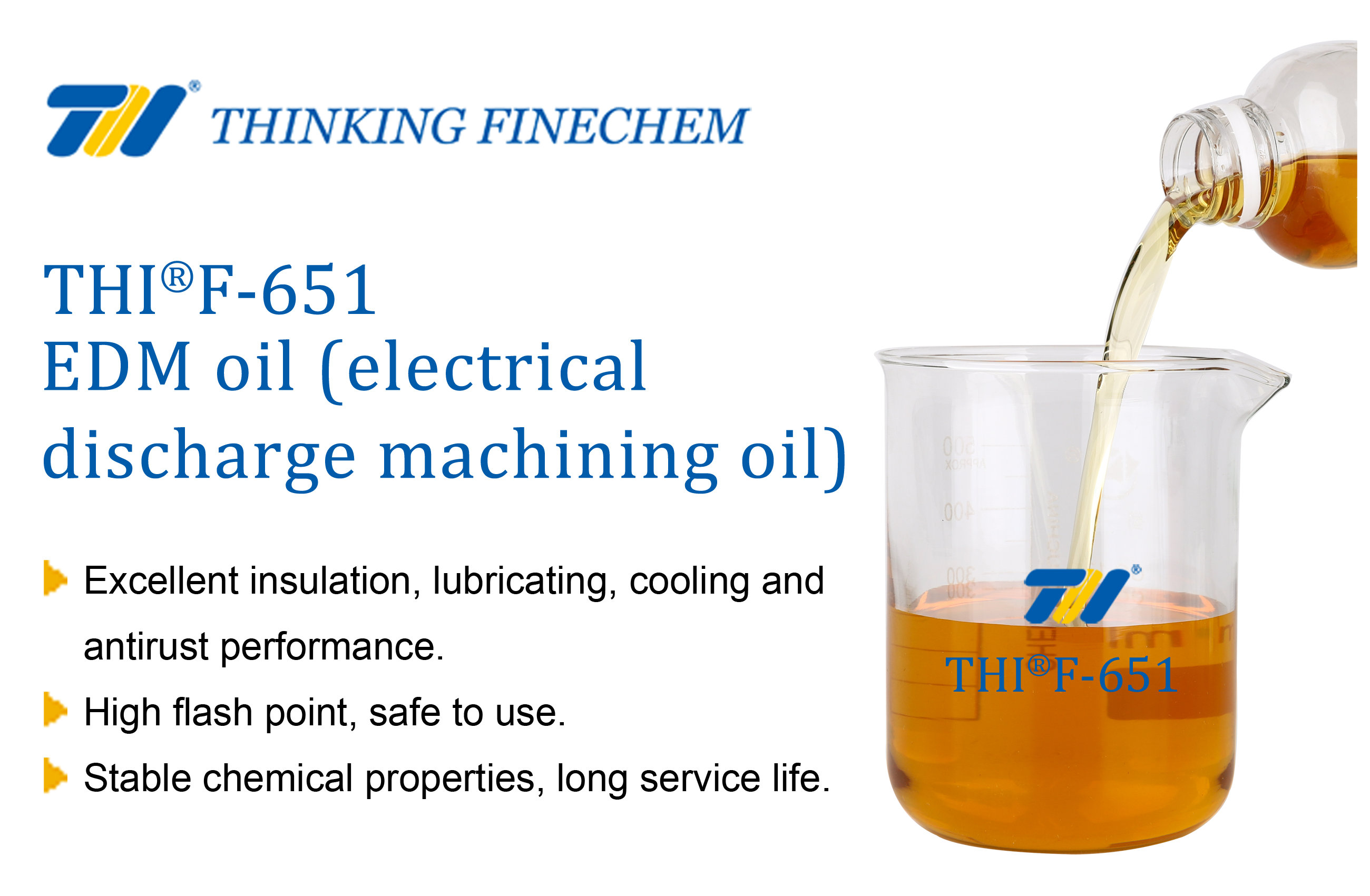

THI®F-651 EDM oil (electrical discharge machining oil)

Brand: Thinking Finechem

Model number:THI®F-651

Appearance: clear amber-colored liquid

package size: 160 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-651

Appearance: clear amber-colored liquid

package size: 160 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is mainly used as the discharge medium of EDM equipment, and has the functions of insulation, lubrication, cooling, drainage, washing, rust prevention, and deionization. This EDM oil has low viscosity, high flash point, high boiling point, fast cooling rate, good oxidation stability, and can perform high frequency and short pulse interval electric discharge machining operations. It can perform precision molding processing safely and efficiently.

①Low viscosity, the range of viscosity is 1.6-2.6mm2/s, 40℃). It has good fluidity, good permeability between electrodes, good washing and slagging performance, fast separation and precipitation of eroded particles.

②It has high flash point of 100-115℃, which is less likely to cause spark oil ignition. It is relative safe to use. It can increase the processing speed of heavy discharge (rough machining), and can increase the average etching rate by 300-500mm3/min.

③Extremely strong chemical stability: The product has no peculiar smell when undergo desulfurization, dearomatization, and hydrogenation treatment. The performance is stable and no deteriorate. It has high boiling point, narrow distillation range, low volatilization loss rate, and has more than two years of service life.

④The cooling effect is remarkable due to the special refrigerant contained. The product is colorless and transparent and easy to observe changes.

②It has high flash point of 100-115℃, which is less likely to cause spark oil ignition. It is relative safe to use. It can increase the processing speed of heavy discharge (rough machining), and can increase the average etching rate by 300-500mm3/min.

③Extremely strong chemical stability: The product has no peculiar smell when undergo desulfurization, dearomatization, and hydrogenation treatment. The performance is stable and no deteriorate. It has high boiling point, narrow distillation range, low volatilization loss rate, and has more than two years of service life.

④The cooling effect is remarkable due to the special refrigerant contained. The product is colorless and transparent and easy to observe changes.

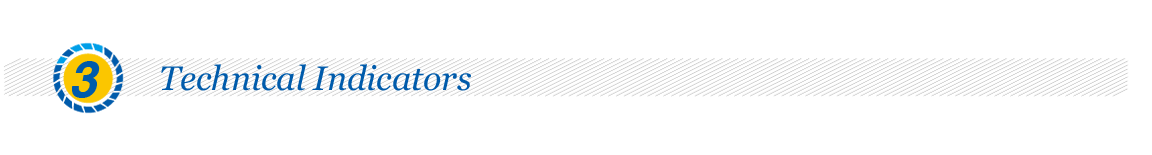

| Subject | Indicator |

|---|---|

| Appearance | clear amber-colored, no stratification, no precipitation, uniform liquid |

| Antirust test, 35±2℃ RH≥95% single sheet 24h | No corrosion, no obvious discoloration |

| Kinematic viscosity 40℃,mm2/s ≯ | 2.0-3.0 |

| Flash point (open), ℃ ≮ | 100-120 |

| Flash point (closed), ℃ ≮ | 80 |

| Initial boiling point ℃ ≯ | 235 |

| End boiling point ℃ ≮ | 305 |

| Aromatics content %≮ | 0.05 |

| Sulphur content ppm≮ | 1 |

| Pour point, ℃≮ | -3 |

| Boiling range (IBP-EP℃) | 250-270 |

| Oxidation resistance | good |

It is suitable for the wire drawing process of copper and aluminum.

Dilute at a ratio of 1:10-1:15 before use.

170KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.