METALWORKING CHEMICALS

-

Forging releasing agent

-

Water-soluble quenching medium

-

Quenching oil

-

cutting fluid

-

Antirust agent

-

Metal cleaning agent

-

Water-glycol based fire-resistant hydraulic fluids

-

Welding anti-spatter

-

Pickling and passivation paste for stainless steel

- Corrosion inhibitor /fogging inhibitor

-

Special lubricants

-

Water treatment agents

THI®F-728 mold release agent for forging

Brand: Thinking Finechem

Model number:THI®F-728

Appearance: transparent colorless or yellowish liquid

PH:9.0-13.0

package size: 25, 200 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®F-728

Appearance: transparent colorless or yellowish liquid

PH:9.0-13.0

package size: 25, 200 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product can effectively replace the graphite release agent. It has an excellent mold release effect at normal working temperature. It is an ideal eco-friendly release lubricant for the hot die forging and hot precision forging of ferrous and non-ferrous metals. It is widely used in forging, extrusion, metal molding and other industries.

①Colorless, odorless, non-flammable, non-corrosive to workpieces and molds.

②Excellent lubricity, good mold releasing performance, effectively prolonging the service life of the mold.

③It has good cleaning and cooling performance; it combines mold washing and demolding together.

④ There is no residue or precipitation, and the surface quality of the forging is not affected.

⑤Good heat resistance, non-volatile at high temperature forging, eco-friendly.

②Excellent lubricity, good mold releasing performance, effectively prolonging the service life of the mold.

③It has good cleaning and cooling performance; it combines mold washing and demolding together.

④ There is no residue or precipitation, and the surface quality of the forging is not affected.

⑤Good heat resistance, non-volatile at high temperature forging, eco-friendly.

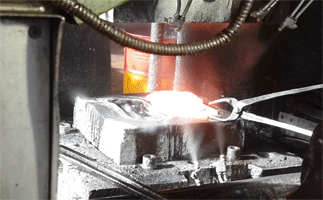

Suitable for forging, extrusion and molding processing of ferrous metals such as steel, copper, aluminum and non-ferrous alloys. Suitable for various hot forging, warm forging, cold forging and other processes.

①It can be applied by spraying and brushing; the general amount of usage is 5%-10% of the total volume.

②When spraying, pour the release agent into the tank, then add water (tap water is can be used), according to the proportion. Close the lid tightly, press the compressed air pipe, and mix it for about 5 seconds, then it can be used for production. If the company does not have a pressure vessel, mix the raw materials with water and manually stir for two minutes before spraying.

②When spraying, pour the release agent into the tank, then add water (tap water is can be used), according to the proportion. Close the lid tightly, press the compressed air pipe, and mix it for about 5 seconds, then it can be used for production. If the company does not have a pressure vessel, mix the raw materials with water and manually stir for two minutes before spraying.

①Before spraying the release agent, make sure that the surface of the mold is free of rust or other impurities, and then apply the release agent.

②When spraying the release agent for the first time, increase the spraying amount accordingly. It is better to pre-spray first, and then spray again during forging.

③The sprayed mold release agent must be evenly distributed on the surface of the mold, and no corner should be left. The amount of spraying should be increased at the corners of the mold.

②When spraying the release agent for the first time, increase the spraying amount accordingly. It is better to pre-spray first, and then spray again during forging.

③The sprayed mold release agent must be evenly distributed on the surface of the mold, and no corner should be left. The amount of spraying should be increased at the corners of the mold.

25KG, 200KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.