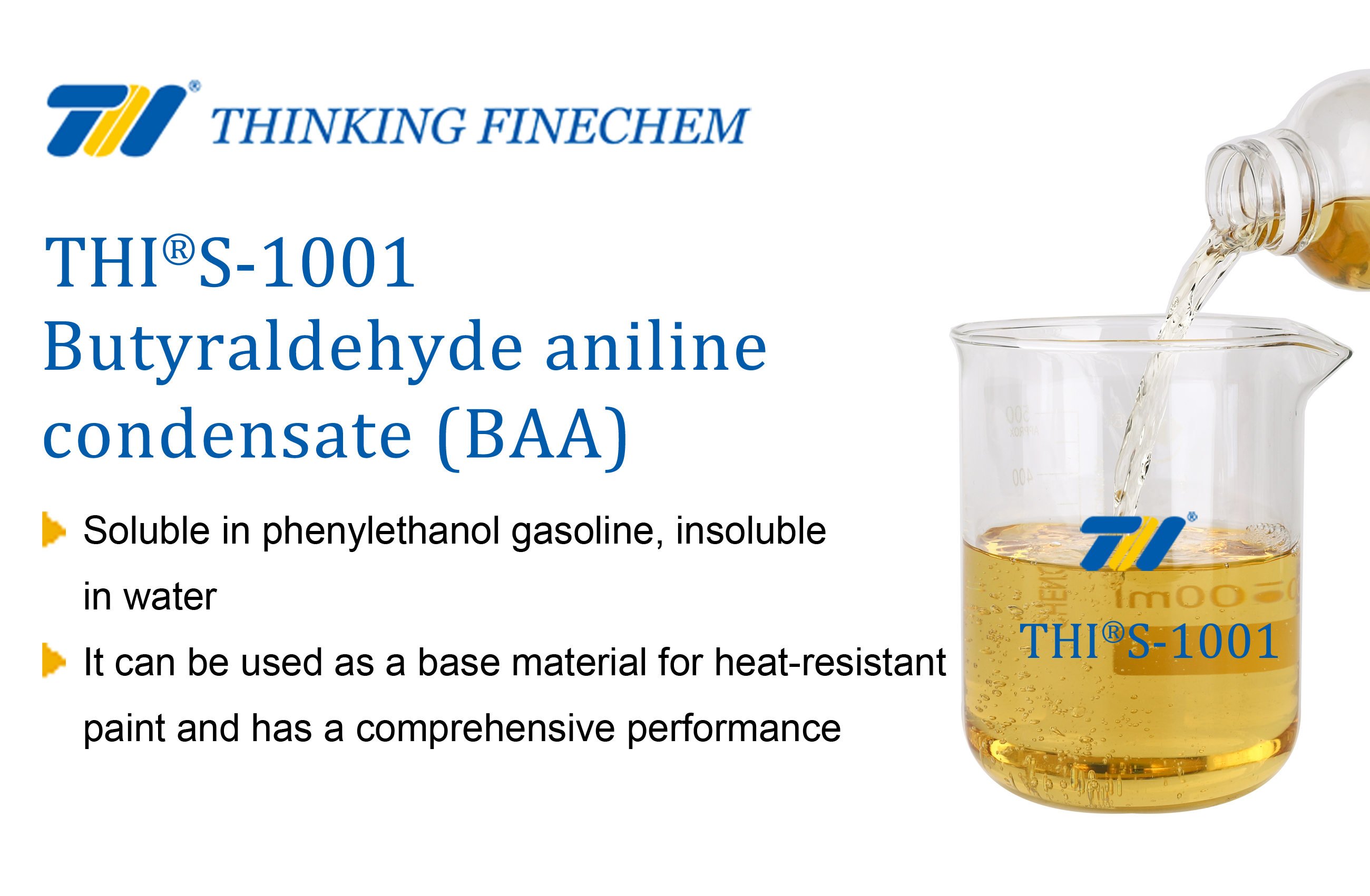

THI®S-1001 Butyraldehyde aniline condensate (BAA)

Brand: Thinking Finechem

Model number:THI®S-1001

Appearance: transparent amber-colored liquid

Specific gravity (20℃):1.004-1.009

package size: 25, 200, 1000 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®S-1001

Appearance: transparent amber-colored liquid

Specific gravity (20℃):1.004-1.009

package size: 25, 200, 1000 KG / bucket

For sample and more info, please contact us (Email: info@thinkingchem.com)

THIS-1001 n-butyraldehyde aniline condensate (accelerator 808) can be used as a vulcanization accelerator for thiadiazole vulcanization crosslinking agent and can be used alone as an accelerator in the production of latex thread or in the curing process of anaerobic glue. It can also be added to polyurethane paint to reduce the baking temperature of the paint film, it increases the adhesion of the paint film to the metal and makes the surface of the paint film smooth.

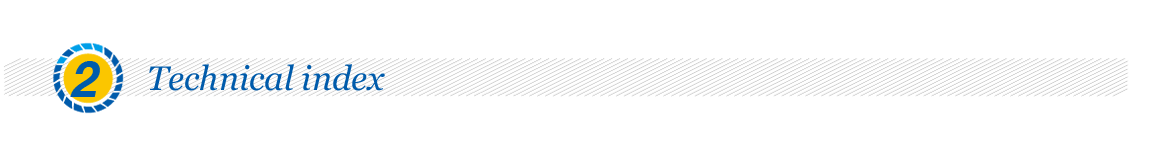

| Subject | Indicator |

|---|---|

| Appearance | transparent amber-colored liquid |

| Solubility | Soluble in phenylethanol gasoline, insoluble in water |

| Flammability | Non-flammable |

| Refractive index at 20℃ | 1.500-1.600 |

| Specific gravity (20℃) | 0.9-1.0 |

| Purity | ≥85% |

① Used in halogen-containing compounds such as chlorinated polyethylene, polyvinyl chloride, chlorohydrin rubber, neoprene, chlorosulfonated polyethylene rubber, and chlorinated rubber to reduce the vulcanization temperature and shorten the vulcanization time.

② It can be used as a base material for heat-resistant paint and has a comprehensive performance. It improves the hardness and adhesion of the paint film, and promotes better overall ductility.

③ it is an excellent surface treatment agent for metal powder for making metal powder paint.

④it can be used as the curing accelerator and modifier of polyester paint and enameled wire paint. It can reduce the baking temperature of the paint film, increase the adhesion of the paint film to the metal, make the surface of the paint film smooth, and improve the solvent resistance, aging resistance, Wear resistance and mechanical strength of the paint film.

⑤ It can also be used as a curing accelerator for silicone resin paint, it can reduce the curing temperature of silicone paint and improve heat resistance.

⑥ It can also be used alone as an accelerator in the production of latex thread or in the curing process of anaerobic glue.

⑦adding this product to some paints can obtain an antioxidant effect. It can inhibit the skinning and wrinkling of the paint film, improve the durability of the paint film, reduce the tendency of chalking, and improve the gloss retention and the wettability of the color pigment.

⑧ it can form heat-resistant paint with aluminum powder or zinc powder which has good anti-corrosion performance under normal temperature and high humidity conditions.

② It can be used as a base material for heat-resistant paint and has a comprehensive performance. It improves the hardness and adhesion of the paint film, and promotes better overall ductility.

③ it is an excellent surface treatment agent for metal powder for making metal powder paint.

④it can be used as the curing accelerator and modifier of polyester paint and enameled wire paint. It can reduce the baking temperature of the paint film, increase the adhesion of the paint film to the metal, make the surface of the paint film smooth, and improve the solvent resistance, aging resistance, Wear resistance and mechanical strength of the paint film.

⑤ It can also be used as a curing accelerator for silicone resin paint, it can reduce the curing temperature of silicone paint and improve heat resistance.

⑥ It can also be used alone as an accelerator in the production of latex thread or in the curing process of anaerobic glue.

⑦adding this product to some paints can obtain an antioxidant effect. It can inhibit the skinning and wrinkling of the paint film, improve the durability of the paint film, reduce the tendency of chalking, and improve the gloss retention and the wettability of the color pigment.

⑧ it can form heat-resistant paint with aluminum powder or zinc powder which has good anti-corrosion performance under normal temperature and high humidity conditions.

It is used as a dispersant in polyurethane paint. It is added during grinding or during the paint mixing stage. The recommended amount of addition is 0.2% of the total amount. The optimal amount of addition should be determined by trials.

It can be used with thiadiazole vulcanization crosslinking agent during the vulcanization process. The recommended ratio of accelerator 808: thiadiazole vulcanization crosslinking agent is 0.8:2.5.

It can be used with thiadiazole vulcanization crosslinking agent during the vulcanization process. The recommended ratio of accelerator 808: thiadiazole vulcanization crosslinking agent is 0.8:2.5.

This product is easy to oxidize. If it is not used up once opened, the remaining product needs to be protected by nitrogen. If there is no nitrogen protection, the color of the product will deepen, but it will not affect the performance and properties of the product. It is forbidden to store and dispose this product in places where people can eat, drink and smoke. Keep it in the original container or an approved replacement container. Keep it tightly closed when it is not in use. Protect the package of butyraldehyde aniline condensate from direct sunlight, keep it away from incompatible materials, and store it in a dry, cool, and ventilated place. Use appropriate controls to avoid environmental pollution.

25KG, 200KG, 1000KG/bucket packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.