DEFOAMER APPLICATION

-

Defoamers for metalworking fluid

-

Defoamers for fermentation industries

-

Defoamers for sewage disposal

-

Defoamers for power plants

-

Defoamers for construction material

-

Defoamers for water-based adhesive

-

Defoamers for textile industries

-

Defoamers for coating and ink industries

-

Defoamers for papermaking industries

-

Defoamers for petroleum industries

-

Defoamers for pesticide and fertilizer industries

-

Defoamers for beneficiation

DEFOAMER COMPONENT

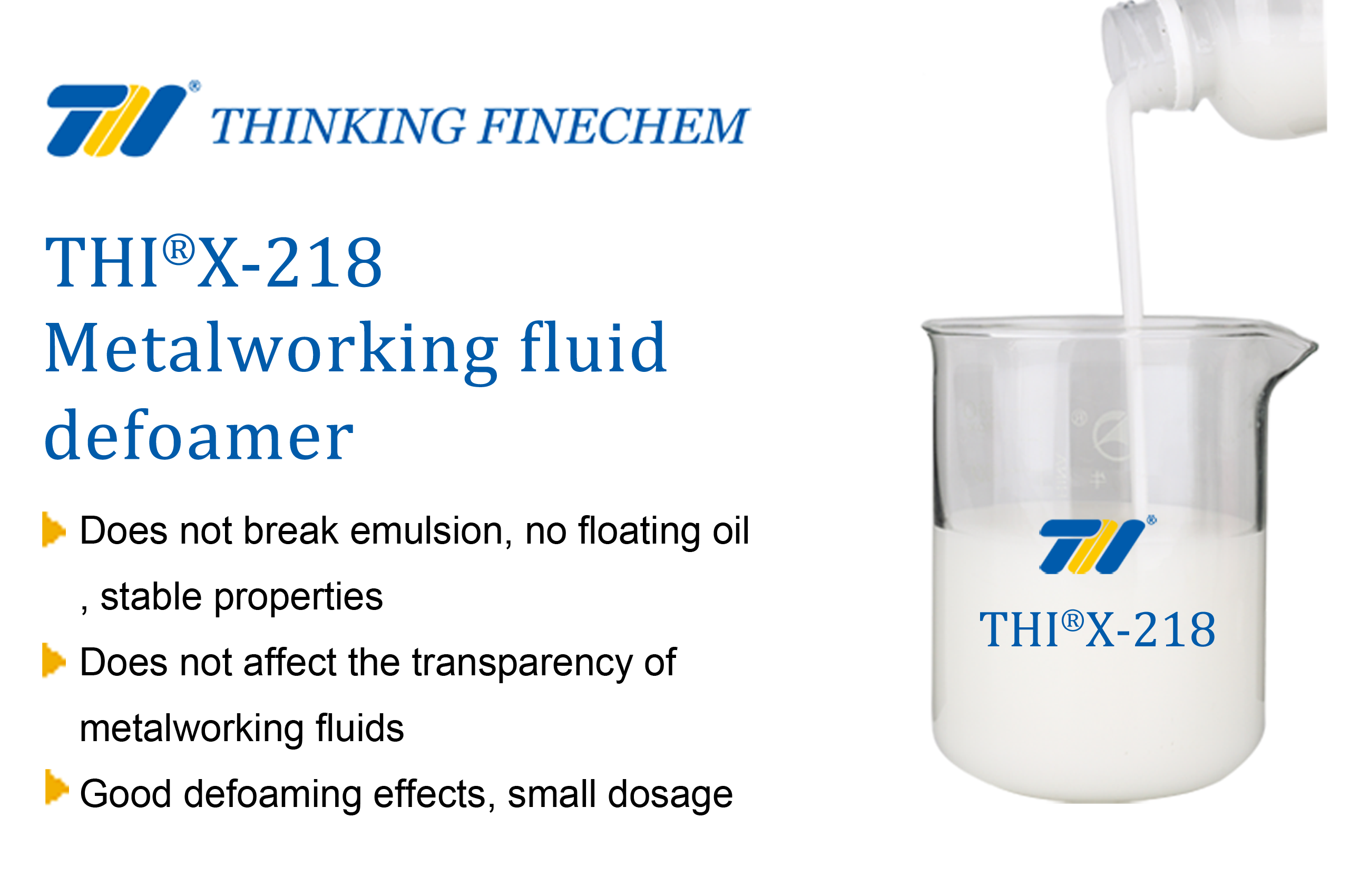

THI®X-218 metalworking fluid defoamer

Brand: Thinking Finechem

Model number:THI®X-218

Appearance: milky white liquid or colorless liquid

PH:6.0-9.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®X-218

Appearance: milky white liquid or colorless liquid

PH:6.0-9.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This defoamer is specially developed for lubrication, cooling, cleaning, anti-rust fluids, etc. It controls foam throughout the metal production process, and it is suitable for defoaming under high temperatures, strong acids and alkalis, high shear, high pressure, and other harsh conditions.

① Excellent defoaming effect, small dosage, does not affect the properties and transparency of the metal working fluid.

② No floating oil or precipitate..

③ Good dispersibility and permeability, fully compatible with metal working fluid..

④ Stable chemical properties, heat resistant, acid and alkali resistant, can still maintain good defoaming effect under high shear force and high pressure conditions..

⑤Can be used in acid, alkali, salt, electrolyte and hard water..

⑥Non-corrosive to metals, no adverse side effects, non-flammable and non-explosive.

② No floating oil or precipitate..

③ Good dispersibility and permeability, fully compatible with metal working fluid..

④ Stable chemical properties, heat resistant, acid and alkali resistant, can still maintain good defoaming effect under high shear force and high pressure conditions..

⑤Can be used in acid, alkali, salt, electrolyte and hard water..

⑥Non-corrosive to metals, no adverse side effects, non-flammable and non-explosive.

| Model No. | THI®X-218A | THI®X-218B | THI®X-218D |

|---|---|---|---|

| Appearance | milky white liquid | Colorless viscous liquid | Colorless viscous liquid |

| PH | 6.0-9.0 | 5.0-7.0 | 1.0-4.0 |

| Centrifugal stability (3000r/min*30min) | No separation | No separation | No separation |

Suitable for all kinds of metal working fluids, such as cutting fluids, hydraulic fluids, cleaning agents, antifreeze fluids, wire cutting fluids, fine grinding fluids, degreasing agents, mold release agents, electroplating solutions, electrolytes, polishing solutions, dehydrating agents.

It can be directly added to the solution. The amount of addition of this defoamer is 0.05-0.2%. The optimal amount of addition should be adjusted by the customers according to the specific situations. If dilution is needed, the dilution ratio should not exceed 1:2. stir evenly before use.

25KG, 200KG, 1000KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.