DEFOAMER APPLICATION

-

Defoamers for fermentation industries

-

Defoamers for sewage disposal

-

Defoamers for power plants

-

Defoamers for construction material

-

Defoamers for water-based adhesive

-

Defoamers for textile industries

-

Defoamers for coating and ink industries

-

Defoamers for papermaking industries

-

Defoamers for petroleum industries

-

Defoamers for pesticide and fertilizer industries

-

Defoamers for metalworking fluid

-

Defoamers for beneficiation

DEFOAMER COMPONENT

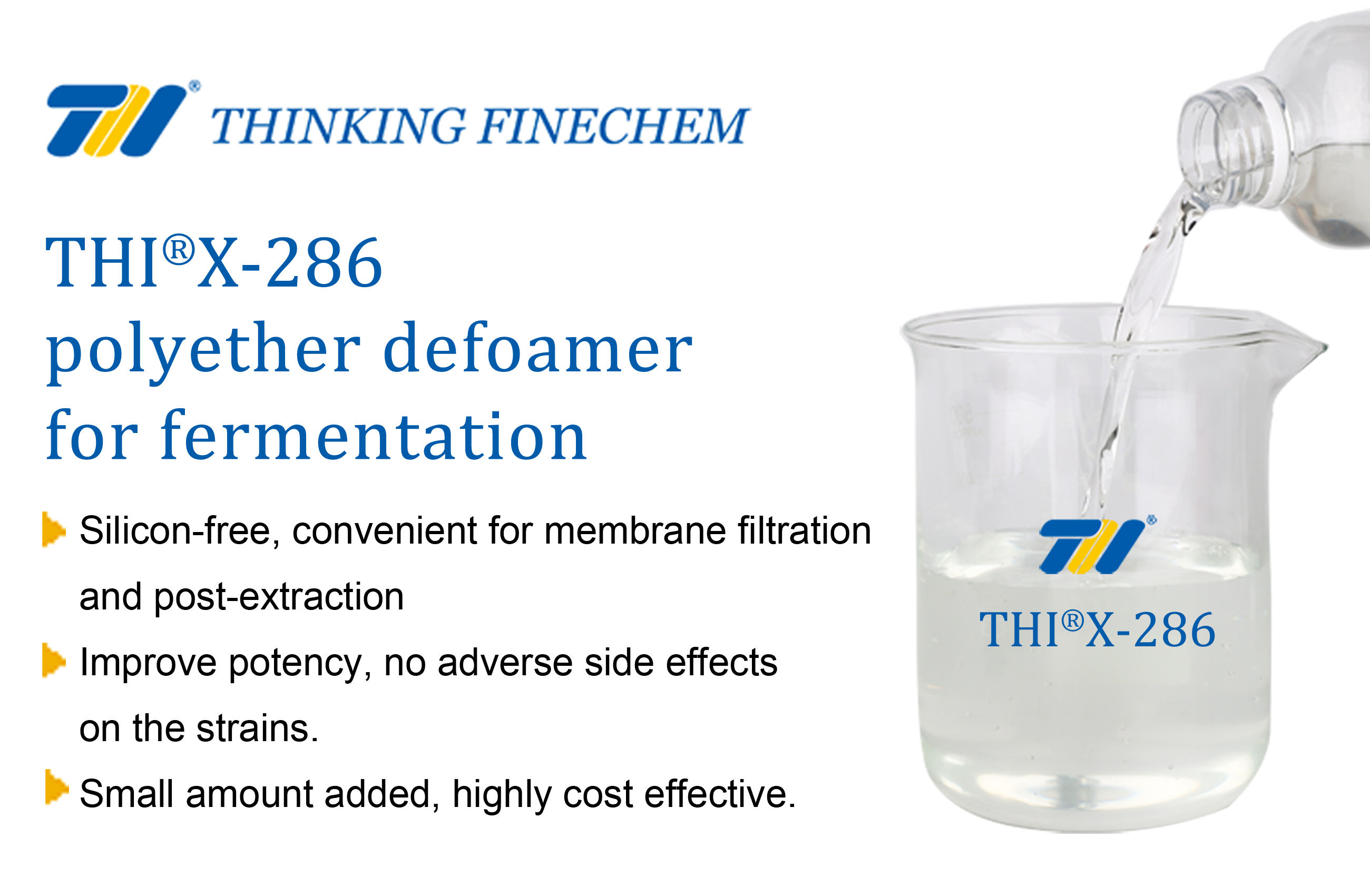

THI®X-286 polyether defoamer for fermentation

Brand: Thinking Finechem

Model number:THI®X-286

Appearance: transparent colorless or yellowish liquid

PH:5.0-7.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®X-286

Appearance: transparent colorless or yellowish liquid

PH:5.0-7.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is a new type of polyether defoamer targeted to the foaming features of the fermentation system. This product can meet the requirements of foam control throughout the fermentation cycle. This defoamer is silicon-free. Comparing to silicon defoamers, this product does not to break emulsification under high temperature conditions and is convenient for membrane filtration and post-extraction.

①Fast-defoaming, long-lasting foam suppression effect, good heat resistance and excellent stability.

②It is helpful to improve the growth environment of strains and increase the potency. It is easy to separate in the later stage of fermentation and the extraction is simple.

③The fermentation tank is easy to clean after fermentation. The product is highly safe for strains and does not affect the basic properties of the foaming system.

②It is helpful to improve the growth environment of strains and increase the potency. It is easy to separate in the later stage of fermentation and the extraction is simple.

③The fermentation tank is easy to clean after fermentation. The product is highly safe for strains and does not affect the basic properties of the foaming system.

| Subject | Indicator |

|---|---|

| Appearance | Transparent colorless or yellowish liquid |

| Odour | No pungent odour |

| Impurity | No visible impurity |

| PH | 5.0-7.0 |

| Hydroxyl value, mgKOH/g | 54.0-58.0 |

| Acid value, mgKOH/g | ≤0.05 |

| Viscosity (25℃), mpa.s | 400-700 |

| Moisture content, % | ≤0.05 |

Suitable for defoaming in fermentation process of glutamic acid, citric acid, lysine, leucine, arginine, dibasic acid, oxytetracycline, chlortetracycline, neomycin, abamectin, colistin, spinosyn, vitamin C, vitamin B2, enzyme Q10, erythritol, yeast and other microorganisms.

The defoamer product can be added in the basic material or be fed into the tank at the later stage. Add the defoamer to the tank after direct steam sterilization. The amount of addition is 0.05%-0.1%.

25KG, 200KG, 1000KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.