DEFOAMER APPLICATION

-

Defoamers for papermaking industries

-

Defoamers for fermentation industries

-

Defoamers for sewage disposal

-

Defoamers for power plants

-

Defoamers for construction material

-

Defoamers for water-based adhesive

-

Defoamers for textile industries

-

Defoamers for coating and ink industries

-

Defoamers for petroleum industries

-

Defoamers for pesticide and fertilizer industries

-

Defoamers for metalworking fluid

-

Defoamers for beneficiation

DEFOAMER COMPONENT

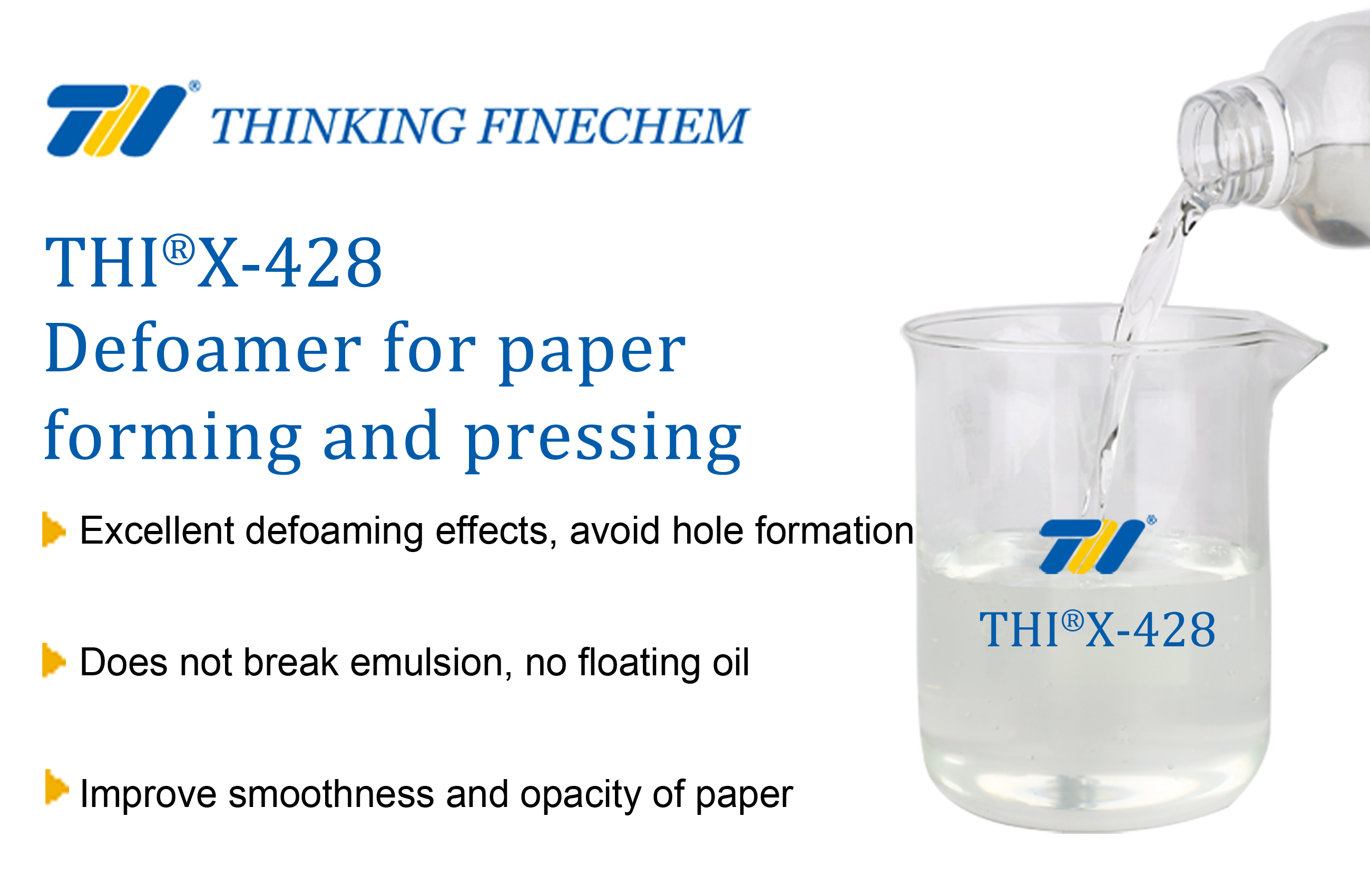

THI®X-428 defoamer for paper forming and pressing

Brand: Thinking Finechem

Model number:THI®X-428

Appearance: transparent liquid

PH:5.0-7.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

Model number:THI®X-428

Appearance: transparent liquid

PH:5.0-7.0

package size: 25, 200, 1000 KG / barrel

For sample and more info, please contact us (Email: info@thinkingchem.com)

This product is a polyether defoamer developed for the foaming problems in paper forming and pressing processes. This product cannot be affected by temperature, which improves production efficiency and protects the operation of the paper machine. It is mainly used in white water treatment, circulating water treatment, and circulating water film treatment.

① Excellent defoaming effect, reduce negative impact of foam on papermaking, avoids formation of holes, reduces paper breaks, and prevent overflow from the storage tank.

②Small dosage, easy to use, no adverse side effects, does not break emulsion, no floating oil.

③Can be completely dehydrated, improve the efficiency of papermaking and enhance the strength of the paper web.

④Improve the retention rate of filler, reduce the filler content in white water, reduce the loss and thus reduce the cost of papermaking.

⑤Reduce the concentration and ash content of the pulp slurry ready to be screened and extend the life of the paper sheet to be formed.

⑥It can remove fiber and wet end chemicals, improve the smoothness and opacity of the paper, thus improving the quality of the paper. This is helpful for the coating and printing processes.

②Small dosage, easy to use, no adverse side effects, does not break emulsion, no floating oil.

③Can be completely dehydrated, improve the efficiency of papermaking and enhance the strength of the paper web.

④Improve the retention rate of filler, reduce the filler content in white water, reduce the loss and thus reduce the cost of papermaking.

⑤Reduce the concentration and ash content of the pulp slurry ready to be screened and extend the life of the paper sheet to be formed.

⑥It can remove fiber and wet end chemicals, improve the smoothness and opacity of the paper, thus improving the quality of the paper. This is helpful for the coating and printing processes.

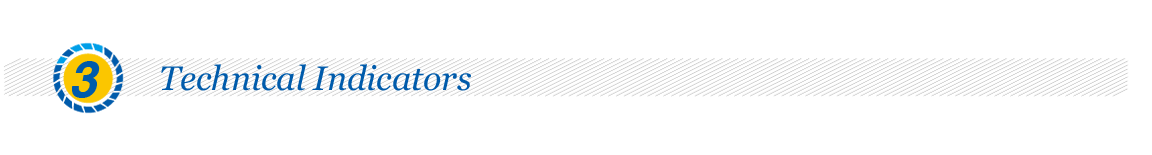

| Subject | Indicator |

|---|---|

| Appearance | Transparent liquid |

| PH | 5.0-7.0 |

| Odour | No obvious odour |

| Solubility | Completely soluble in water, good dispersibility |

It is suitable for defoaming in various kinds of paper production such as coated paper, printing paper, kraft paper, newsprint paper, tissue paper, etc. It can also be used as a defoaming component for papermaking chemicals or it can be used in the production of rosin sizing agent.

① It can be added directly in the production process or it can be added after dilution. It is recommended to use a metering pump to add the defoamer to places where the defoamer is easy to disperse, such as the white water tank under the screens and the white water outside the machine.

② The approximate amount of use is 0.2-0.5% of the finished product. Due to the differences of production processes, the optimal amount should be determined through testing.

② The approximate amount of use is 0.2-0.5% of the finished product. Due to the differences of production processes, the optimal amount should be determined through testing.

25KG, 200KG, 1000KG/barrel packaging. Please store in cool places. The storage life is 2 years. Transported as general chemicals.